Mercadona is the leading Spanish food retailer, supplying its customers in Spain and Portugal… Read more »

Mercadona is the leading Spanish food retailer, supplying its customers in Spain and Portugal… Read more »

AR Racking and Swisslog have started the installation of a new clad-rack warehouse in… Read more »

Sofia-based intralogistics specialist STAMH has provided a mobile racking system at Bitola, North Macedonia… Read more »

Frozen food producer Hesbaye Frost has commissioned BA Systèmes to replace its entire AGV… Read more »

Global integrator Witron is building the sixth fully automated frozen food logistics centre for… Read more »

The STEF Group announced its takeover of part of the activities of the Marconi… Read more »

Oakland International is a UK third party logistics (3PL) services provider that specialises in… Read more »

Guest post by Philip K. Diekhöner, Innovation Strategist & Author, Singapore One of the… Read more »

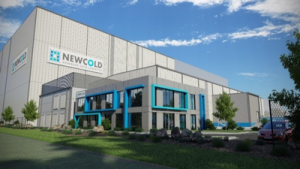

Temperature-controlled company NewCold Advanced Cold Logistics, which opened its first UK automated frozen food… Read more »

UK frozen food retailer Iceland has signed a new three-year commercial agreement with CHEP,… Read more »

At the end of December 2023, MERCADONA awarded the WITRON Group with the construction… Read more »

When the Samworth Brothers company was looking for a new hanging sign for its… Read more »

Stock-taking in a warehouse is a time-consuming, manual process. Until now. David Priestman visited… Read more »

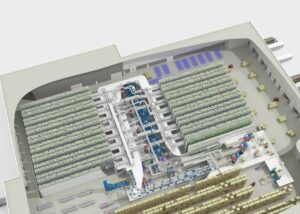

The revolution in food retail logistics began in Parkstein in 2003. Today, the OPM… Read more »

When the Samworth Brothers company was looking for a new hanging sign for its… Read more »

Expanding a highly dynamic multi-temperature logistics centre for roughly 1,200 stores during ongoing operations… Read more »

Global supply chain software provider EPG (Ehrhardt Partner Group) has announced another major client… Read more »

Helmut Prieschenk from Witron (pictured) and Franziskos Kyriakopoulos, founder of 7LYTIX from Linz, Austria,… Read more »

Johannes Schweiger (pictured) is managing director of Witron Service GmbH + Co. KG and… Read more »

We turn our attention to the Jungheinrich PowerCube as we continue our look at… Read more »

For the expansion of their existing logistics infrastructure, retailers have for a long time… Read more »

As the world becomes more focused on sustainability, businesses across all industries are exploring… Read more »

Autonomous Mobile Robots will contribute significantly to efficient and productive use of increasingly vital… Read more »

Last July, British freight and warehouse service provider PML issued a statement regarding the… Read more »

Leading UK packaging supplier, Kite Packaging, has launched an innovative ventilated pallet wrap ideal… Read more »

Warehouse space does not come cheap, but for frozen and chilled products companies, the… Read more »

Yorkshire, UK-based temperature-controlled food storage and distribution (TSC&D) firm, Reed Boardall, has battled through… Read more »

Logistics specialist Gist has launched an extensive trial in the UK of DAF’s LF… Read more »

Oakland International has promoted Stuart Pugh to deputy site operations manager at its warehouse… Read more »

Highly dynamic, supermarket logistics centres need to be durable and flexible. Two big Witron… Read more »

Total supply chain solutions provider Oakland International has announced the appointment of Jas Sittre… Read more »

Thermo King, a leader in transport temperature control solutions and a brand of Trane… Read more »

Everyone likes oranges and tangerines in wintertime. But not too many of us know… Read more »

Peli BioThermal, the life science industry’s partner from discovery to distribution, has revealed its… Read more »

That last mile in the delivery supply chain is one of the toughest for… Read more »

UniCarriers has won the Materials Handling Equipment Provider of the Year Award at the… Read more »

A specialist safety installation to secure racking frames in a chilled store in Dublin,… Read more »

Dutch online supermarket Picnic trusts in the expertise and experience of intralogistics specialist TGW… Read more »

We’ve reached the final category of our run-through of each of the IFOY Award… Read more »

With online food delivery revenues predicted to reach €43bn/£37bn in the European Union this… Read more »

Fresh fish and e-commerce – how does that work? Víctor Escancianon (pictured), Director of… Read more »

Phil Swinn, Special Projects Manager at Thermal Printer Support Ltd (TPS), a leading UK… Read more »

E-Wrap, Sitma‘s new e-commerce wrapper, will be on display at Ipack-IMA, from 3rd to… Read more »

ParcelHero says ‘Putin’s War’ is already having an impact on costs, supply chains and… Read more »

A 1,608-solar panel system developed, designed, and installed by BeBa Energy has been completed… Read more »