With Schauer Gabelstapler GmbH, Clark Europe has brought a new sales partner for Austria… Read more »

With Schauer Gabelstapler GmbH, Clark Europe has brought a new sales partner for Austria… Read more »

Austrian Post has selected INFORM’s Yard Management System (YMS) for their Yard Excellence Tool… Read more »

After an implementation period of more than two years, SPAR Österreichische Warenhandels AG and… Read more »

Hellmann Worldwide Logistics opened its first Austrian Direct Load branch in Kufstein this February.… Read more »

A new first regular train Rail Cargo connection has been launched from the Croatian… Read more »

As the official logistics partner of the Austrian Space Forum (OeWF), Gebrüder Weiss is… Read more »

At its production site in Pinkafeld, Austria, Austrotherm produces energy-saving insulating panels. An automatic… Read more »

Kellner & Kunz, an Austrian specialist for tools, fastening technology and C-parts is preparing… Read more »

Austrian wholesaler Kellner & Kunz is going on the offensive with the expansion of… Read more »

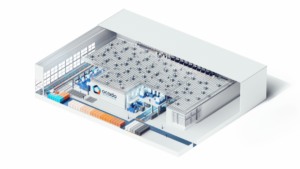

Aberle has rebuilt intralogistics for plastic manufacturer Greiner Bio-One International. Storing capacity in the… Read more »

DKV Euro Service has expanded its supply network in Austria, allowing DKV customers to… Read more »

European warehouse investor-developer P3 Logistic Parks says it has pre-let the whole of its… Read more »

Automated materials handling solutions specialist TGW Logistics has developed a revolutionary system for fully… Read more »

The UTLC Eurasian rail alliance has announced new deals in Austria and Kaliningrad. Owned… Read more »

Union Tank Eckstein GmbH & Co. KG (UTA) has appointed a new Country Manager… Read more »

Austria’s VTG Rail Logistics are to offer higher rail capacity from Hungary. The company’s… Read more »

Austria’s Unterer GmbH is expanding its existing fleet of 605 vehicles with 105 new… Read more »

Dachser is investing about €6.5 million in a new 20,000 sqm facility in Stans… Read more »

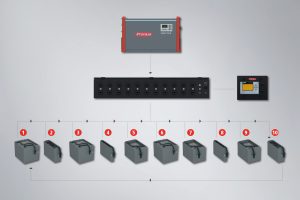

Guaranteed cost reductions for battery charging Austrian battery maker Fronius has unveiled its suite… Read more »

In support of its on-going growth strategy, TGW Logistics Group is expanding its head… Read more »

Kalmar, part of Cargotec, has been awarded a valuable order from long-standing partner Osterreichische… Read more »

In response to today’s high demand for resilience in the world of physical operations,… Read more »

Bold new branding for end-to-end system integration specialists TGW Logistics represents confidence, flexibility and… Read more »

The production of confectionery in Holešov, Czech Republic, has a long tradition dating back… Read more »

Gebhardt Intralogistics Group and Ocado Intelligent Automation (OIA) are entering into a relationship wherein… Read more »

LKW WALTER is celebrating its 100th anniversary and can look back on a century… Read more »

While Girteka is traditionally a road-focused company with a fleet of over 6,000 trucks… Read more »

Körber, a global provider of warehouse management system (WMS) solutions, announced today that it… Read more »

ABB and crane builder Kuenz, headquartered in Austria, have secured the largest single order… Read more »

HWArobotics showcased its high quality, reliable and efficient shuttle automated storage and retrieval systems… Read more »

At LogiMAT 2024, DS Automotion will showcase the results of 40 years of expertise… Read more »

The IFOY organization has announced the nominations for the IFOY AWARD 2024 and once… Read more »

NIPPON EXPRESS HOLDINGS, INC., is pleased to announce that, in accordance with the share… Read more »

Lödige Industries, a global supplier of material handling systems, has received certifications for quality… Read more »

The international transport and logistics provider cargo-partner has made significant contributions to various charity… Read more »

It is among the most cutting-edge in the world: the new company site for… Read more »

Rohlig SUUS Logistics, a logistics operator in Central and Eastern Europe, has opened its… Read more »

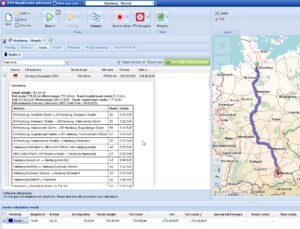

PTV Logistics today announced the availability of a new toll calculation in PTV Map&Guide… Read more »

On Tuesday November 14th the international transport and logistics provider cargo-partner officially launched the… Read more »

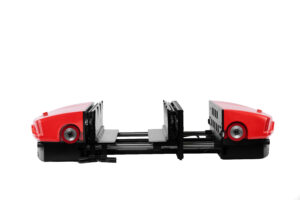

With covers made from locally sourced wood, the new generation of Stingray shuttle saves… Read more »

Arvato and Douglas, a European omnichannel provider for beauty, have jointly officially opened their… Read more »

A new regular common user freight train service was recently launched by Metrans that… Read more »

Dematic has completed the installation at two Weiss Technik sites of stand-alone AutoStore™ systems… Read more »

Helmut Prieschenk from Witron (pictured) and Franziskos Kyriakopoulos, founder of 7LYTIX from Linz, Austria,… Read more »

A new regular common user open rail train service has been launched by Rail… Read more »

CTP has signed deals totalling 96,000 sqm at five of its logistics CTParks across… Read more »

As cargo-partner is celebrating its 40th anniversary, company owner and founder Stefan Krauter has… Read more »

Gebrüder Weiss has opened a logistics terminal in the Kreckelmoos industrial estate in Reutte.… Read more »