Reusable packaging supplier ORBIS Corporation will display its range of solutions for the retail… Read more »

Reusable packaging supplier ORBIS Corporation will display its range of solutions for the retail… Read more »

Cabka-IPS is to present boxes and pallets for efficient food trade at Fruit Attraction.… Read more »

Online action sports retailer, Freestyle Xtreme, has implemented the Snapfulfil cloud warehouse management system… Read more »

Crown has launched the WP 3010 electric pallet truck, extending the forklift manufacturer’s well-established… Read more »

Business is booming for online retailers but only half are happy with their fulfilment… Read more »

German lifestyle retailer Baur has contracted inconso to boost its multi-order picking operations. In… Read more »

‘The State of the Retail Supply Chain 2017’ research study, conducted by research firm… Read more »

Two of the UK’s supply chain specialists have joined forces to create a new… Read more »

XPO Logistics has been awarded a new multi-year contract with Beauty Bay, an independent… Read more »

Businesses and consumers can now be notified when their palletised freight will arrive because… Read more »

According to recent research by Manhattan Associates, two thirds of shoppers say they expect… Read more »

Exertis CapTech, one of the leading distribution specialists in the Nordic countries in the… Read more »

Europe’s largest music retailer Musikhaus Thomann has selected automated handling systems specialist TGW Logistics… Read more »

Macfarlane Packaging, the UK’s largest protective packaging supplier, is hosting a series of unique… Read more »

From today, retail supply chain teams will be able to use the Blue Yonder… Read more »

To ensure fresh carrots and parsnips were delivered to customers on-time during the busy… Read more »

UniCarriers has reacted to its nomination in two categories for the coveted International Forklift… Read more »

UK logistics firm Clipper has released a report of UK consumer retail behaviour in the… Read more »

Proximity and Veeqo today announced a partnership to bring STREAM, a multi-award winning delivery… Read more »

Dematic, the automated intralogistics solutions company, has published a white paper, ‘The Great Grocery… Read more »

Douglas Owen has been appointed Secretary General of the Bureau International des Containers (BIC)… Read more »

Ocado, the world’s largest online-only grocery retailer, is developing 4G-based protocol to communicate with… Read more »

With the busiest retail season of the year under way, UK-based Macfarlane Packaging has… Read more »

CAFOM Group, a major retailer in the household goods sector, has extended its collaboration… Read more »

Fewer retailers will go into the black on Black Friday Returns are up for… Read more »

When Clipper Logistics plc was awarded a new e-fulfilment contract with a major international… Read more »

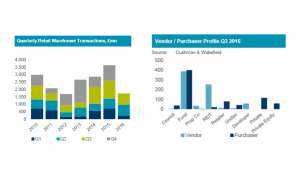

Retail warehouse sales reached £754m in the third quarter the highest quarterly total… Read more »

Goplasticpallets.com has launched Nest M1, the first one-eighth retail pallet to the supply chain… Read more »

Briggs Equipment is helping the UK’s largest specialist manufacturer of zinc alloys to improve… Read more »

A corrugated packaging redesign has resulted in a recyclable and cost-saving logistics solution for… Read more »

Swiss wholesaler and retailer COOP’s newest distribution centre will come online later this month… Read more »

The new SF 800 H Retail Pallet is the latest model to join Goplasticpallets.coms… Read more »