Sixfold, which describes itself as Europe’s leading provider of real-time predictive visibility of shipments… Read more »

Sixfold, which describes itself as Europe’s leading provider of real-time predictive visibility of shipments… Read more »

Insulation business ISOVER has joined the shipment tracking network of real-time predictive visibility specialist… Read more »

Supply chain visibility pioneer Project44 will showcase its gamechanging functionality at transport logistic in… Read more »

Are Retailers Waking up to the Supply Chain Visibility Imperative? Customer demands are a… Read more »

US-based transport logistics software specialist project44 has taken over GateHouse Logistics, the Denmark-based visibility… Read more »

Yusen Logistics has launched what it calls a “pioneering” live track and trace system,… Read more »

CET Designer software maker Configura has released CET Designer 9.0. It includes the ability… Read more »

Supply chain software specialist Manhattan Associates has made updates to its Transportation Management System… Read more »

The UK’s Marks and Spencer (M&S) has selected Zetes to help transform visibility and… Read more »

Alcorta Forging Group, a leading automotive components manufacturer, effectively manages unit-level traceability and has… Read more »

The new fork positioner from Linde Material Handling is designed to offer a significantly… Read more »

CRH Transport, which provides trailer haulage as part of its service offering, has announced… Read more »

Yale Europe Materials Handling has launched the Rider Stacker model MS16S. It follows the… Read more »

Dürr, a publicly traded provider of industrial systems and equipment with 15,200 employees at… Read more »

Unisys Corporation has launched PharmaTrack, new software that combines leading security, advanced data analytics and compliance… Read more »

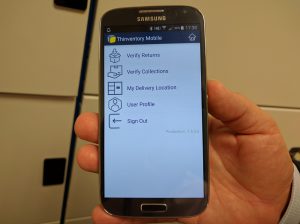

International technology company, ByBox, is launching its latest technological development, Thinventory Mobile, which it… Read more »

The larger and bulkier the loads that have to be moved, the higher are… Read more »

The recently launched Combi-CB70E has earned global recognition for its ergonomic design, performance, and… Read more »

Delivering results is the reason why logistics and shipping support teams are adopting agentic… Read more »

CtrlChain announces the launch of its Shipper Transport Management System (TMS), a SaaS solution… Read more »

In this insightful transport management focused episode of Logistics Business Conversations, Peter MacLeod sits… Read more »

One of the UK’s largest and longest-standing redistributor and retailer of surplus products, Company… Read more »

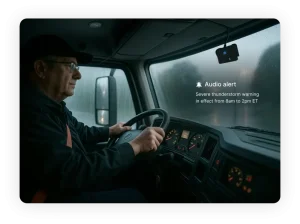

Samsara has just launched more than a dozen new safety and AI-powered tools designed… Read more »

ASOS, a global fashion destination, has announced a collaboration with Celonis to optimise supply… Read more »

A new future for supply chains starts with your partners, writes Scott Lehmann VP… Read more »

Zencargo, a global digital freight forwarder, empowering businesses to make their supply chain a… Read more »

The benefits of e-documentation in logistics are improved collaboration, operational efficiency and substantial reduction… Read more »

Samsara, the pioneer of the ‘Connected Operations Platform’, has announced its Q1 FY26 financial… Read more »

Heating products and electrical cable distributor Pitacs Ltd has selected Forterro’s ERP and Warehouse… Read more »

If you’ve ever walked through the pasta aisle of your local supermarket, chances are… Read more »

Svuum, one of the fastest-growing last-mile delivery companies in Greece, has partnered with FarEye,… Read more »

Manhattan Associates Inc. has announced the launch of Enterprise Promise & Fulfill™, a cloud-native… Read more »

Finnebrogue, one of the UK’s leading and award-winning food producers, has selected RELEX Solutions,… Read more »

Leading express delivery company DPD has signed a partnership with Wise to replace its… Read more »

Agrigem, one of the UK’s biggest distributors of plant protection products, has grown turnover… Read more »

As the logistics sector continues to evolve at pace, the demand for smarter, faster,… Read more »

Körber Business Area Supply Chain celebrated the groundbreaking of its newest manufacturing facility in… Read more »

Manhattan Associates Inc., a global leader in supply chain commerce, has announced an expanded… Read more »

DP World has unveiled a fully integrated logistics and market-entry solution aimed at addressing… Read more »