Element Logic will integrate Addverb solutions for AMRs (autonomous mobile robots) into its existing… Read more »

Element Logic will integrate Addverb solutions for AMRs (autonomous mobile robots) into its existing… Read more »

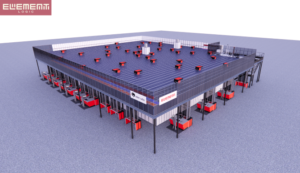

System integrator Element Logic has implemented another AutoStore system in Switzerland. The maximally flexible… Read more »

For its new logistics centre in Bad Homburg, Ellen Wille, a European market leader… Read more »

Element Logic recently attained global distribution rights for sales and implementation of AutoStore, which… Read more »

With more than 100 implemented AutoStore systems around Europe, Element Logic is now entering… Read more »

Element Logic is to implement cube storage solution AutoStore for UK 3PL provider Neovia… Read more »

Element Logic, the first AutoStore partner, has opened an office in France. It is… Read more »

The world’s largest AutoStore warehouse, Boozt, is the first to adopt the new Black… Read more »

Element Logic is launching a robotic piece-picking solution that combines their expertise as AutoStore… Read more »

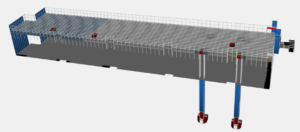

Element Logic’s AutoStore experts are developing cutting-edge robotics technology which they claim has the… Read more »

Nordic systems integrator Element Logic has announced that Eir Bjørkly (above) will take over… Read more »

Nordic logistics automation specialist Element Logic says it is presenting some “revolutionary news” at… Read more »

please click here.

please click here.

Research conducted by transport technology solutions provider, Microlise, has revealed that transport and fleet… Read more »

Ofcom has unveiled proposals to reform the UK’s Universal Service Obligation (USO), aiming to… Read more »

Supply chain volatility is nothing that a fixed-price contract can’t fix, write Sarah Rutnah, Thomas… Read more »

Certificates, pre-let and electricity – what determines warehouse development? The new reality of warehouse investment… Read more »

Autonomous mobile robots optimise the movement of goods in warehouses, logistics centres and manufacturing… Read more »

Schlüter-Systems KG, a the global supplier of system solutions for tile and natural stone… Read more »

Intralogistics customers partnering with Beumer, a provider of warehouse automation technology, can expect step-change… Read more »

With over 150 international attendees representing 92 leading companies in the world of eCommerce… Read more »

Better stock accuracy and planning can be achieved with AI, in the Gulf and… Read more »

A compact and agile AirRob automated storage system by Libiao Robotics has been installed… Read more »

Meachers Global Logistics welcomed MSc students from the University of Southampton to its Nursling… Read more »

Rotating, gripping, protecting – stabau GmbH, formerly Schulte-Henke GmbH, is expanding its portfolio with… Read more »

A ProMat Chicago, AutoStore unveiled its first AI-powered picking robot in the U.S. With… Read more »

Digitalization has emerged as a cornerstone of modern, responsible operations across all industries, and… Read more »

Food logistics provider Nagel-Group is driving forward the digitalisation of its co-packing activities. With… Read more »

Returnable transport packaging (RTP) has moved on significantly since the emergence of that retail… Read more »

Aaron Geiger, Managing Director of Manufacturing and CPG/Retail for ORTEC, looks at Strategies businesses… Read more »

With a strong ambition to grow its existing footprint, smart locker network Bloq.it has… Read more »

Shell Commercial Road Transport’s Aleid van der Wiel discusses how the ‘chicken and egg’… Read more »

The digital transformation of the transport sector and route optimisation shows no sign of… Read more »

Packaging is a critical element in the delivery process, serving not only as a… Read more »

Once again this year, visitors to the META-Regalbau stand in hall 1 – Stand… Read more »

At cargo-partner, a group company of NIPPON EXPRESS HOLDINGS, INC., digitalization is key to… Read more »

Edward Hutchison, Managing Director of BITO Storage Systems UK, explains why successful automated warehouse… Read more »

In May 2023, data obtained by Pinsent Masons revealed that 127 UK companies have… Read more »

Peter MacLeod reports from IFS Unleashed, the software giant’s biennial partner summit in Orlando,… Read more »

There are six key trends in warehouse automation to look out for in 2025,… Read more »

DHL Supply Chain announces the opening of its first warehouse fulfilment centre in Poland… Read more »

![Logistics Business[Podcast] Supply Chains: Evolving Risks and the Path to Resilience](https://www.logisticsbusiness.com/wp-content/uploads/2024/10/Design-9-1-300x300.png)

In this episode of Logistics Business Conversations, host Peter McLeod speaks with Saul Resnik, CEO… Read more »

The transport and logistics industry has successfully fielded two strong teams of riders to… Read more »