Logistics service provider Van den Bosch will celebrate its sixtieth anniversary in October 2024.… Read more »

Logistics service provider Van den Bosch will celebrate its sixtieth anniversary in October 2024.… Read more »

Whether storing, conveying, weighing and dosing, or loading and unloading, Nord Drivesystems says it… Read more »

Neustädter Hafen remains an important hub for breakbulk transports to North America: Norlat Shipping… Read more »

The retail of big and bulky goods is often fraught with logistical issues and… Read more »

Leading robotics and automation company, RMGroup, has supplied one of its industry-leading bulk bagging… Read more »

Two bulk handling specialists have joined forces to combine their sixty years of experience… Read more »

South Pacific International Container Terminal (SPICT) in Lae, Papua New Guinea recently handled its… Read more »

Oceaneering International has launched a new business, OceanSMART Cargo Logistics and Maritime Technology, which… Read more »

Geodis, one of the world’s leading global supply chain operators, will be exhibiting at… Read more »

Suttons Tankers has agreed a deal to acquire DHL Supply Chain’s UK bulk commodity… Read more »

German multidirectional forklift maker Hubtex will present its latest model developments at May’s LIGNA… Read more »

Schoeller Allibert’s new standard foldable intermediate bulk container (IBC) is designed for international logistics.… Read more »

Abbey has upgraded its fleet with an investment in 28 Volvo FH tractors to… Read more »

GEODIS will be a Gold Sponsor at this year’s Breakbulk Europe at Messe Bremen,… Read more »

Abbey Logistics Group has been selected by Tata Chemicals Europe to manage exclusively all… Read more »

Multidirectional sideloaders enable the safe and efficient handling of long and bulky goods –… Read more »

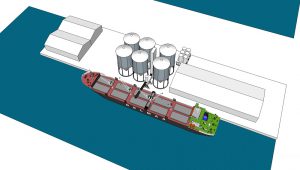

Belfast harbour now has a new bulk storage facility that provides a safe haven… Read more »

Abbey Logistics Group, one of the UK’s largest bulk liquid and powder transport providers,… Read more »

NorthEdge Capital has invested an undisclosed eight-figure sum for a significant majority stake in… Read more »

Asset-based freight forwarder, UWL, has launched a new proprietary solution for shipping non-hazardous bulk… Read more »

Cabka-IPS has come up with a potential solution for the efficient handling of bulk… Read more »

Newport Industries is set to invest £7m in the creation of a new bulk… Read more »

On Monday 16 November, in Antwerp, Belgium, a jury of port operators brought together… Read more »

Flogas Britain, one of the UKs leading LPG, LNG and alternative energy suppliers has… Read more »

The larger and bulkier the loads that have to be moved, the higher are… Read more »

With the new META CLIP shelf trolley, META has launched an innovative solution for… Read more »

DP World has signed a 30-year concession agreement with Syria’s General Authority for Land… Read more »

The recently launched Combi-CB70E has earned global recognition for its ergonomic design, performance, and… Read more »

Global Energy Storage Group (GES) has announced the completion of the sale of its… Read more »

Schenk UK is proud to announce the successful start of a major long-term gas… Read more »

Inotec is proud to introduce its latest innovation in smart labelling – RFID Inmould… Read more »

Tate & Lyle Sugars continue to push sustainability with the introduction of two brand-new… Read more »

DP World Egypt marked a significant milestone last week with the arrival of the… Read more »

ArrowXL, one of the UK’s largest and longest established two-person home delivery specialists, has… Read more »

There’s a new warehouse labelling innovation in town: Drytack. It’s a reusable, residue-free alternative… Read more »

Eurosort recently appointed Rens Gehling as its new Commercial Director, with a brief to… Read more »

Direct-to-Consumer (D2C) eCommerce sales keep increasing. Good news for retailers, logistics and warehouse operators,… Read more »

What exactly does Extended Producer Responsibility entail, and how should logistics businesses respond? Carrie… Read more »

The national logistics centre in Neu-Isenburg is part of an extensive initiative by the… Read more »

The Hubtex Group, consisting of Hubtex Maschinenbau GmbH in Fulda, DIMOS Maschinenbau GmbH in… Read more »

With rising labour, fuel and packaging costs, many companies today are seeking solutions that… Read more »

DELIVER Europe, a matchmaking event for retail and supply chain, is thrilled to announce… Read more »

Ocado Intelligent Automation (OIA), part of Ocado Group, has introduced Porter AMR, a pallet-moving… Read more »