Kinaxis (TSX: KXS), a global leader in supply chain management, is bringing its patented… Read more »

Kinaxis (TSX: KXS), a global leader in supply chain management, is bringing its patented… Read more »

Volvo Trucks has signed a letter of intent to sell 1,000 electric trucks between… Read more »

DHL Supply Chain today announces the introduction of the UK’s first fully electric Volvo… Read more »

Volvo Trucks has now sold more than 4,300 electric trucks globally in more than… Read more »

Volvo Group Venture Capital has invested in the Swedish tech company Adnavem. With an… Read more »

Michelin says tyres from its X Line Energy range – designed for fleets seeking… Read more »

Global logistics provider Kuehne+Nagel has put eight new Volvo FH Globetrotter LNG (Liquified Natural… Read more »

DHL Parcel is investing £6.7m in an upgrade to its fleet of trucks and… Read more »

Mike Corcoran has been appointed Acting Managing Director Volvo Trucks UK & Ireland. He… Read more »

Volvo Trucks UK has reported successful trials for a limited-edition FH16-750 after it recently… Read more »

Neil Park has been appointed as Regional Managing Director for Volvo Truck and Bus… Read more »

Volvo Trucks says it is now taking yet another important step in the development… Read more »

Volvo Trucks says its unique powertrain is now more efficient than ever before. With… Read more »

This is an entirely unique combination that gives the driver perfect steering feel and… Read more »

This is an entirely unique combination that gives the driver perfect steering feel and… Read more »

In Reality Road, Volvo Trucks TV series, a Volvo FH is subjected to a… Read more »

Camden Group, one of the UK and Irelands leading manufacturers and suppliers of PVCu… Read more »

Tate & Lyle Sugars continue to push sustainability with the introduction of two brand-new… Read more »

Girteka has signed a major deal with Volvo Trucks to purchase 2,000 brand-new heavy-duty… Read more »

Kinaxia Logistics has added the first fully-electric Volvo HGV to its fleet as the… Read more »

The BMW Group is driving the future of emission-free heavy-duty transport – with pilot… Read more »

DHL Supply Chain has announced the acquisition of Inmar Supply Chain Solutions, a division… Read more »

Don-Bur, British supplier of commercial vehicle bodywork, has delivered 16 newly designed 13.6m long… Read more »

Heavy Goods Vehicles are well-suited to the use of hydrogen for carbon-free transport fleets… Read more »

Logistics service provider Van den Bosch will celebrate its sixtieth anniversary in October 2024.… Read more »

In this eBook, entitled Decarbonisation of Transport Operations, Editor Peter MacLeod delves into the… Read more »

Global logistics company DSV has signed an agreement with Volvo Trucks to purchase 300… Read more »

In the rapidly evolving world of logistics, the shift towards sustainable transport solutions is… Read more »

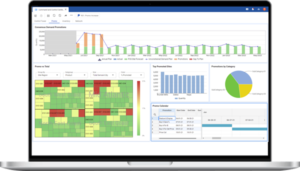

Today, the quality of road transportation services relies heavily on the skills and expertise… Read more »

A haulage alliance between Davies Turner and D.Perfect & Sons, that is celebrating its… Read more »

Kinaxis® Inc. (TSX: KXS), a global leader in end-to-end supply chain orchestration, has announced… Read more »

Kinaxis Inc. , a global leader in end-to-end supply chain orchestration, has announced that… Read more »

The transition to electric vehicles is not just a trend; it is one of… Read more »

The automotive industry’s reliance on its supply chain running smoothly is important to ensure… Read more »

The logistics sector is actively seeking sustainable solutions to environmental challenges. But what are… Read more »

Today’s main challenge in the logistics and transport sectors is decarbonisation. Electric trucks, intermodal… Read more »

The collapse of the Baltimore bridge is a tragedy. But the impact on supply… Read more »

Kinaxis, a global provider of supply chain management solutions, announced a strategic expansion of… Read more »

In the world of logistics and supply chain automation, few stories are as compelling… Read more »

Farming and haulage company, Pearn Wyatt & Son, has taken delivery of two bulk… Read more »

A lower chassis and battery-powered too – they are the main features of a… Read more »

Efficient internal benchmark processes are essential for every transport service provider. RIO is setting… Read more »

For the third consecutive year, real-time supply chain visibility company FourKites has been named… Read more »

Emitting only water vapour, hydrogen-powered fuel cell trucks will be an important part of… Read more »

Skaraslättens Transport is Sweden’s biggest provider of container transport on the roads, hauling 850-900… Read more »

Maritime Transport, the UK’s leading provider of integrated road and rail solutions, has turned… Read more »

With its Web Events, WABCOWÜRTH offers customers and interested parties an informative service about… Read more »