Multi-client shuttle system put into operation at Harsewinkel

3rd March 2022

Arvato Supply Chain Solutions is expanding Harsewinkel, Germany into its leading healthcare location in Europe. To this end, a new multi-client-capable shuttle warehouse with picking system has now been put into operation at the North Rhine-Westphalia site, which in the future will enable the products of a total of 25 customers from the pharmaceutical and medical technology industry to be shipped even more efficiently and quickly to hospitals, pharmacies, doctors, laboratories, patients and wholesalers. At the same time, Arvato is using the new shuttle solution to drive forward the automation strategy for its global sites.

“The healthcare market is currently being shaped by the trend toward more and more direct deliveries from pharmaceutical and medical technology manufacturers to their customers. This makes automation useful in healthcare logistics as well,” says Dr. Thorsten Winkelmann, Managing Director Healthcare at Arvato Supply Chain Solutions.

“It allows us to respond more flexibly and efficiently to changing market needs, ensure optimal patient care and grow together with our customers.”

The appropriate automation solution was determined after a detailed analysis of inventory and delivery volumes and the structure of the products. For this purpose, Arvato has its own Logistics Engineering department, whose experts have clustered different automation technologies independently of manufacturers according to application standards as in a modular system. From this, the modules for each project are then put together individually on the basis of the respective requirements.

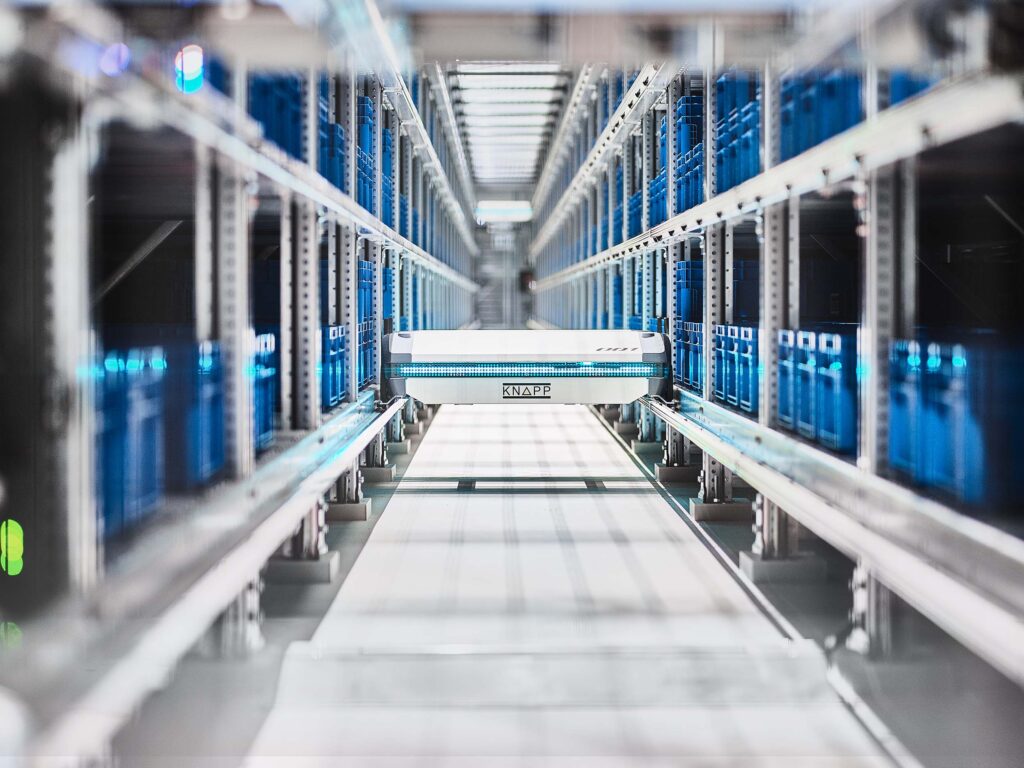

“In addition, since the space conditions in Harsewinkel were predefined and could not be expanded at will, we opted for a state-of-the-art shuttle system with stacked bins from our service provider KNAPP,” explains Fabian Generotzky, Vice President Operations Healthcare at Arvato in Harsewinkel.

With the increased storage density in the shuttle in this way, around 4,300 sq m of additional storage space have been gained, which is now available for growth with existing and new customers.

For the implementation, the Healthcare division was able to draw on the experience and expertise of other successful automations by Arvato Supply Chain Solutions. Generotzky adds: “The implementation in an existing facility during ongoing operations was nevertheless one of the most complex projects in the history of Arvato Healthcare.”

A challenge that was mastered with great commitment from everyone involved. The shuttle warehouse, which extends over three floors in Harsewinkel, has a total capacity of 55,000 storage locations for 44,000 totes and 11,000 shipping cartons. 84 shuttles move in the system in five aisles and can switch between the individual levels via six elevators.

For efficient order processing, pharmaceutical and medical products are conveyed directly to six picking stations using the goods-to-person principle. Additional work areas for order picking and goods issue are connected to the system via high-performance conveyor and sorter technology. During packing, semi- and fully-automatic carton erecting machines support the dispatch processes.

“The output per aisle is 400 to 650 movements per hour,” says Generotzky. “With each movement, the robotic vehicle both stores and retrieves goods – so there are no empty runs. This improves throughput by up to 10%, so it’s ideal for processing high volumes and boosts efficiency throughout the value-added process of warehouse logistics.”

The customer structure at the site also spoke in favour of using a shuttle. “In Harsewinkel in particular, we look after very different clients, so it is not possible to foresee a pronounced ABC distribution of products,” adds Generotzky. “With the shuttle, you quickly have direct access to the products and, compared to other automation solutions, you don’t need any lead time to get the items out of the system.”

With the new shuttle system in Harsewinkel, Arvato Supply Chain Solutions is well equipped for further growth. Generotzky concludes: “We have built generously and planned for capacity expansions in order to be able to react quickly to the increasing demand on the market, but also from existing customers.”