Megadyne introduces ‘game-changing’ rubber belt

28th September 2022

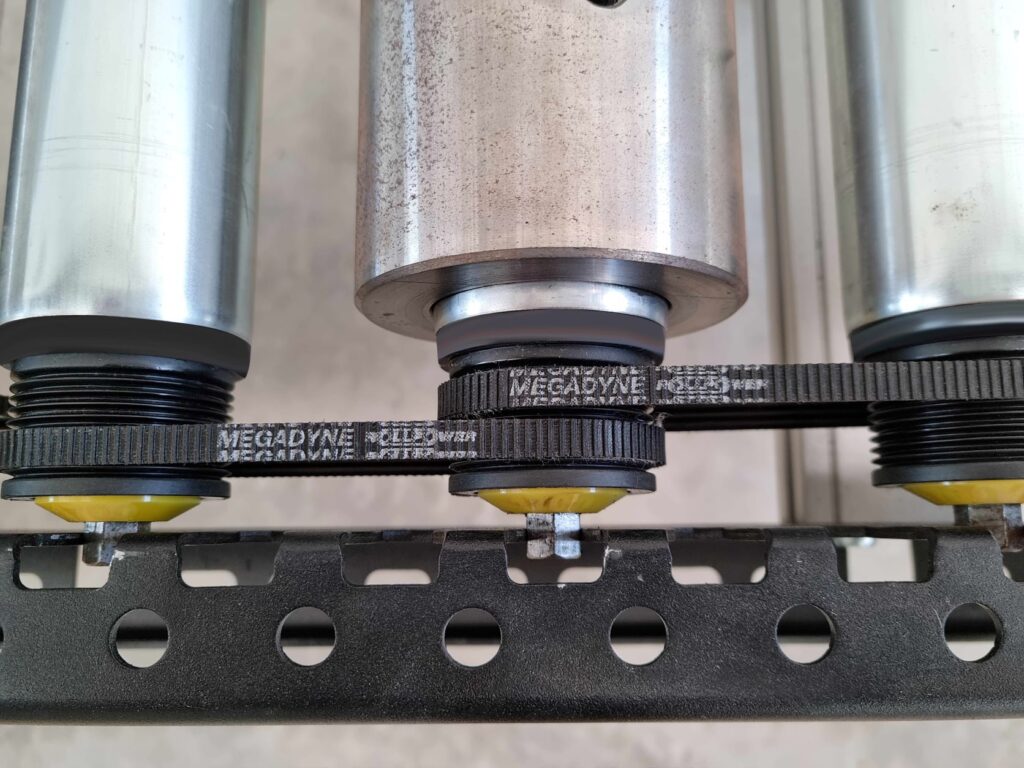

Megadyne, a recognised leader in the world of power transmission solutions for logistics, has introduced what it describes as a new game changer – Megadyne Rollpower. This recent development is a high-performance elastic ribbed rubber belt that requires less maintenance than standard options and offers savings on energy consumption.

The logistics industry has been calling for an innovation, because today, more than ever, the warehouses and distribution centres are under the pressure of time. They are required to run longer and at higher speeds without sacrificing the precision and efficiency of performance.

The Megadyne Research and Development Centre has recognised these needs and proposed a matched solution Rollpower, which is designed with an extra-strong elastic polyamide cord tension members for greater flexibility and extended belt life. Rollpower eliminates the need for frequent replacements, and its antistatic qualities prevent the accumulation of dust and dissipated electrostatic charges. The wide working temperatures, from -40°C to 120°C, make it operable in a variety of working conditions.

Though Rollpower has been originally developed with logistics applications in mind (including receiving lines, order picking, sortation, transfers and diverters), it may also be a suitable match for the world of domestic appliances and fitness.

What Are the Benefits?

Rollpower means improved efficiency. It provides stable tension, together with smooth, reliable and quiet running. Because of the resistance to wear, aging and abrasion, the life of the belt is extended. This, in turn, translates into cost savings. The belt can reduce energy requirements by up to 5%.

The installation is fast and easy. Rollpower is able to run even 50 rollers together. There is no need to use idlers or tensioners. No slippage occurs because of the precision of rib design and accumulated sidewall friction.

This innovative solution requires also less maintenance. The process of replacement and installation is simple, and the line downtime is significantly reduced.