FB Chain to showcase uptime-enhancing conveyor components at RWM 2016

9th August 2016

Throughout its 30-year history

FB Chain has acted not only as

a supplier to the recycling and

waste management sectors

of conveyor and roller chains,

sprockets, pins, bushes, rollers

and attachments but also as a

design consultant, helping

customers to achieve the very

best performance from their

conveyor operations.

FB Chains Inno scraper

attachments made from

multi-laminated beech, for

example, were originally designed

to combat the costly

consequences of overloading

experienced by recycling

customers in Germany. When

customers traditional steel

scrapers (from another supplier)

had buckled under pressure,

causing irreparable damage

to chains, sprockets and even

chipping units and furnaces, FB

Chain came to the rescue with a

range of wooden flights that

simply snap when overloaded.

While just as durable, FB Inno

scrapers cause no damage to

surrounding components, are

simpler, quicker and cheaper to

replace and at one tenth of the

weight of traditional steel

scrapers, they dramatically

reduce stress on conveyor

drives, not to mention energy

running costs.

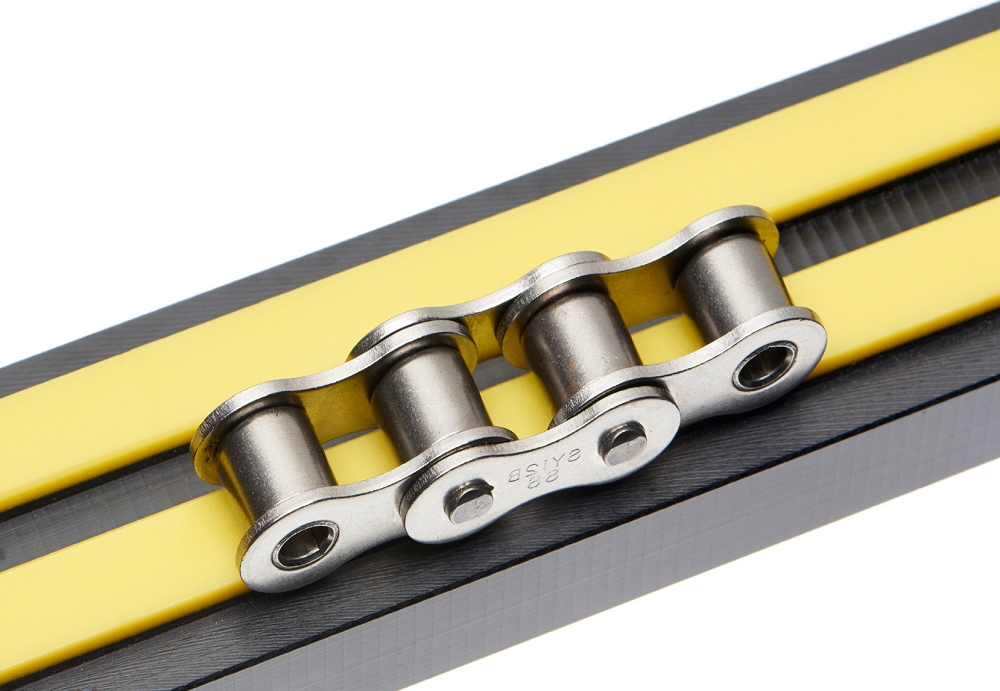

FB Chains two-colour

polyethylene wear strips,

meanwhile, were first developed

for a biomass customer in the UK

to help better manage

replacement schedules. In

FB Chains unique design two

contrasting coloured plastics

are layered over each other

and as soon as the base colour

becomes visible through the top

layer, technicians know that it is

time to replace the chain guide.

This visual cue acts as a

convenient built-in wear

indicator. Technicians do not

need to stop the conveyor to

check the degree of wear and it

ensures they are replaced at the

optimum time not too early,

generating unnecessary

expenditure, and not too

late when damage could

be caused to the conveyor

chain.

Just as these key

innovations help to keep

customers conveyors

up and running, so too

do FB Chains popular

self-cleaning sprockets

with induction-hardened

teeth made from

corrosion-resistant steel.

The grooves around the

edge of each sprocket

prevent loose material

from becoming trapped

between the teeth,

reducing maintenance

requirements and

increasing the life of the

sprocket.

FB Chain will be

showcasing each of

these industry-leading

products, alongside its

portfolio of conveyor and

roller chains, at the at the

forthcoming RWM exhibition, taking

place at the NEC in Birmingham

13th15th

September.

FB Chains

representatives

will be on hand

to discuss

materials,

coatings and

attachments,

as well as other

design challenges

specific

to the recycling

and waste

management

industries.

At FB Chain we

dont just

supply

conveyor

components, rather we work

together with customers to

develop innovative solutions that

overcome their individual

challenges and boost the

performance of their entire

conveyor including efficiency,

ease of maintenance, service

life and total cost of ownership,

says Darran Green, sales

manager at FB Chain. We are

very much looking forward to

meeting with new customers at

RWM in September and having

some stimulating discussions

about how to solve their conveyor

problems.

Find out more at

www.fbchain.com.