Buckle up for an Evolution in Pallets US-Style

17th August 2016

In addressing eco-challenging landfill waste issues, more and more companies are looking for ways to “go green” with their packaging products by leveraging eco-friendly, sustainable, biodegradable, or natural alternatives.

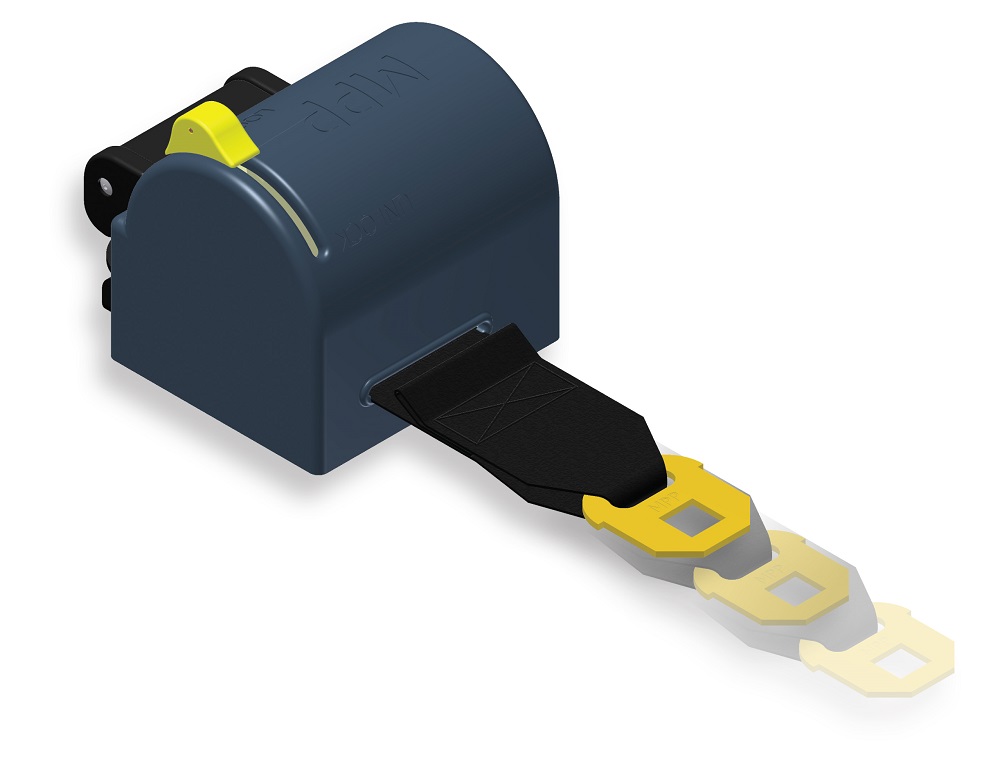

Midwest Precision Products, Inc, based in Ohio, USA, has provided retractable, reusable, self-contained cargo restraints for material handling applications since 1992. In a continuing effort to advance sustainable packaging solutions, MPP has been collaborating with one of the oldest thermoforming and structural foam moulding companies in Michigan, Robinson Industries, to create eco-friendly systems that combine their Seatbelts for Pallets with Robinsons returnable synthetic pallets.

Over 50% of Robinsons materials are recycled vs. virgin resin on their products?using extruded plastic flat sheets, which are injection moulded, thermoformed, and vacuumed down. Ultimately, the system is made with a structural foam base and vacuum form lid with totes placed between them. Two trays will make up a layer, and multiple stacks go up based on client need. The MPP retractable belts simply attach and reattach per repeatable loading/unloading operations.

Key MPP Seatbelt Specs:

- 59-to-148 working length using 1 or 2 wide black polyester seatbelt style webbing.

- Male tongue end attaches to female style buckle.

- Unit is spring biased to retract at all times. Unit will take-up webbing slack at all times.

- All steel components are corrosion resistant with zinc plating or powder coating.