With warehouse staff reaching their performance limits in processes that demand high performance and… Read more »

With warehouse staff reaching their performance limits in processes that demand high performance and… Read more »

UK health food wholesaler Queenswood Natural Foods has adopted Voiteq’s VoiceMan Warehouse Execution System… Read more »

Goplasticpallets.com has launched new tray geared for the fruit-picking industry. The GoEuro 64120LP, a… Read more »

International supply chain solutions provider TouchPath – www.touchpath.com – is extending its ‘TouchWMS’ warehouse… Read more »

TGW Logistics has announced the launch of FlashPick® – a smart piece-picking system which… Read more »

Intralogistics specialist Kardex Remstar UK has launched its LR 35 Vertical Buffer Module onto… Read more »

Swedish specialist HelgeNyberg is offering hints, tips and advice via its digital service called… Read more »

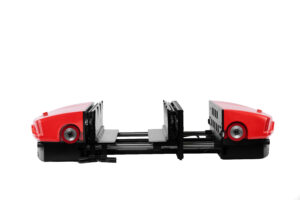

Mitsubishi design engineers have created game changing innovation with a low level order picker… Read more »

-300x200.jpg)

One of the most powerful and the largest construction group in the world will… Read more »

UniCarriers is expanding its range of order pickers. The Tokyo-based concern is now offering… Read more »

Omnichannel retail is imposing a radical shift in logistics practices. When you drill right… Read more »

Stefan Engelson is the owner and CEO of Engelsons whos selling hunting- and leisure… Read more »

The first installation of KNAPPs Pick-it-Easy Robot solution is operating successfully at the site… Read more »

In response to new challenges in the grocery sector, SPAR Austria has taken delivery… Read more »

Xinjia Pharmaceutical, a distributor of pharmaceutical products, automatized its two DCs in Xinjiang, China.… Read more »

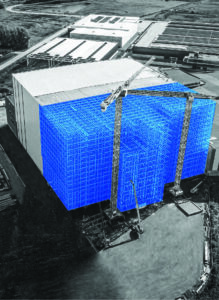

At the end of December 2023, MERCADONA awarded the WITRON Group with the construction… Read more »

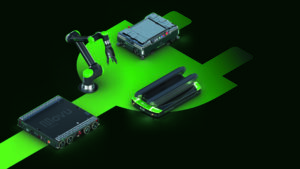

Körber announced today the launch of three solutions set to augment and elevate warehouse… Read more »

Yale Lift Truck Technologies has added an order picker pallet truck to its line-up… Read more »

A new Webinar from Logistics Business is now available to watch on-demand. In association… Read more »

Leading Finnish logistics services provider Inex Partners Oy has partnered with SEE to enhance… Read more »

Smart automation solutions for the entire inbound and outbound logistics and intralogistics process are… Read more »

Companies aiming to improve their competitiveness through more highly automated intralogistics will find everything… Read more »

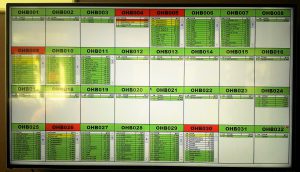

HWArobotics showcased its high quality, reliable and efficient shuttle automated storage and retrieval systems… Read more »

Cimcorp is a pioneer in intralogistics solutions, simplifying material flows and improving customers’ profitability… Read more »

To enhance its affordable desktop and mobile printer ranges, TSC Printronix Auto ID today… Read more »

Coesia, a leader in innovative industrial and packaging solutions, will showcase its internal logistics… Read more »

Briggs Equipment is proud to support the ambitions of businesses in the UK &… Read more »

In his latest byline, Simon Jones (pictured), UK Sales Executive at Exotec, a global… Read more »

Kardex, a world leading manufacturer of automated storage and retrieval systems (ASRS), is presenting… Read more »

Today there is an increasing market demand for simple autonomous solutions with self-navigating vehicles… Read more »

Stepping into the spotlight at LogiMAT 2024, ForwardX Robotics, a Chinese case picking solution… Read more »

The retail company Sport-Tiedje is automating its new logistics centre with driverless transport systems… Read more »

Next day delivery is a logistical challenge that warehouses often require an upgrade to… Read more »

Fives will present its complete ecosystem of smart and automated solutions at the LogiMAT tradeshow… Read more »

The automation of hand scanning processes increases productivity at inbound and outbound areas of… Read more »

The February ’24 issue of Logistics Business magazine: 84 pages of exclusive content spanning… Read more »

The pandemic, Brexit, ongoing geopolitical conflicts, and rising inflation have placed unprecedented pressure on… Read more »

JCC Lighting is part of the Leviton Group and is a market leader in… Read more »

stow Group, a global market leader in the development, manufacture and implementation of advanced… Read more »

At LogiMAT 2024, which takes place at the Stuttgart Trade Fair Centre in Germany… Read more »

WEROCK Technologies GmbH, an innovative provider of industrial IT solutions, introduces the Rockscan W100,… Read more »

At the upcoming LogiMAT in Stuttgart, March 19th to 21st, Dematic highlights how every… Read more »

Honeywell (Nasdaq: HON) today announced it will team up with Hai Robotics to deliver… Read more »