Conveyor Systems Ltd (CSL) helped a leading E-Commerce customer to upgrade its packing and… Read more »

Conveyor Systems Ltd (CSL) helped a leading E-Commerce customer to upgrade its packing and… Read more »

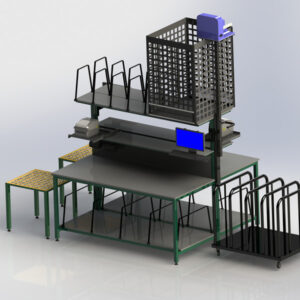

Kite Packaging, a leading online UK packaging supplier, has launched modular custom packing benches.… Read more »

Nulogy’s relationship with CEVA Logistics is continuing to forge ahead after its flexible cloud-based… Read more »

President of the European Federation of Wooden Pallet & Packaging Manufacturers (FEFPEB), Rob van… Read more »

Industrial packing solutions provider MSK is looking at ways to help reduce the amount… Read more »

Dutch fashion store Van Tilburg has chosen the Datalogic Memor 10 to streamline the… Read more »

Pregis Limited has launched the Easypack® Coiler, a high volume, high-speed ancillary packaging solution… Read more »

WaveGrip, manufacturer of innovative beverage multi-packing solutions, is helping Lancaster Brewing Co. increase its… Read more »

-300x200.jpg)

One of the most powerful and the largest construction group in the world will… Read more »

New Hyster® RS46-36CH ReachStackers are considered to form the backbone of the operation at… Read more »

Shared component concept: Top Mosca quality at affordable prices SoniXs technology: Efficient and reliable… Read more »

Almost nine in 10 warehouses pop on the tunes for their workers, as a… Read more »

Leading Finnish logistics services provider Inex Partners Oy has partnered with SEE to enhance… Read more »

TeamViewer, a leading global provider of remote connectivity and workplace digitalization solutions, recently announced… Read more »

Yusen Logistics (UK), a leading provider of logistics solutions, and SEGRO, owner, manager and… Read more »

Hugo Beck is underlining its position as a leading innovator in horizontal film and… Read more »

In his latest byline, Simon Jones (pictured), UK Sales Executive at Exotec, a global… Read more »

About a year after signing a strategic partnership agreement with the German mobile robotics… Read more »

Exhibitors from nearly every sector of the industry are coming to LogiMAT 2024 to… Read more »

Kinaxia Logistics has agreed a three-year contract to provide UK distribution, warehousing and other… Read more »

More and more processes at the end of today’s production and packaging lines are… Read more »

Retail Supply Chain & Logistics Expo is a UK retail focused supply chain &… Read more »

The kickback against the ‘throw-away’ consumer society is gathering pace, with manufacturers under increasing… Read more »

Rohlig SUUS Logistics, a logistics operator in Central and Eastern Europe, has opened its… Read more »

Peak season is a chaotic and profitable time for the majority of retailers and… Read more »

SEGRO has welcomed three new customers to its logistics park in Rainham, as it… Read more »

Knapp, leading technology partner for value chains, is making its MultiScan master data capture… Read more »

Small ecommerce businesses are hugely reliant on the quality and timeliness of parcel delivery… Read more »

Leading sports fashion retailer, JD, has embarked upon a programme of investment into Sparck… Read more »

Dematic has recently completed the implementation of an autonomous mobile robot (AMR) solution for… Read more »

The revolution in food retail logistics began in Parkstein in 2003. Today, the OPM… Read more »

Japan faces a labour shortage impact in 2024 as new overtime regulations for truck… Read more »

Savoye, a leading global warehouse automation integrator and software publisher in the Middle East,… Read more »

CIRRO Fulfillment and Hai Robotics, a pioneer and leader in Autonomous Case-Handling Robot (ACR)… Read more »

Kite Packaging, known for its award-winning and eco-conscious packaging solutions, is launching a paper… Read more »

The seven industry bodies dedicated to container safety, collaborating as the Cargo Integrity Group,… Read more »

Dematic has recently completed commissioning of an automation project featuring innovative warehouse technology for… Read more »

James and James is a third party logistics (3PL) business set up for multiple… Read more »

Southgate Global, formerly known as Southgate Packaging, has announced a repositioning to communicate its… Read more »

Emmeci, a Coesia company in the design and manufacturing of machines and systems for… Read more »

Unisys has unveiled ‘Unisys Logistics Optimization’™, a new quantum-powered solution designed to help organizations… Read more »

Everybody is talking about Artificial Intelligence but what are its potential applications for warehousing… Read more »

Dexterity AI has announced a collaboration with FedEx Corp. to leverage AI-powered robotic technology… Read more »

According to a recent report by MHI and Deloitte (1), 74% of leaders asked… Read more »

Supply quality and first-class on-site services are crucial if retail pharmacies are to survive… Read more »

Escalating costs and continued demand for warehouse space are placing ever greater pressure on… Read more »

Leading online packaging supplier, Kite Packaging, has added a new, hamper-sized ecommerce box to… Read more »

With consumer spending under pressure and online return rates of between 20 – 30%,… Read more »