The choice of lithium-ion forklift options is set to step up a gear with… Read more »

The choice of lithium-ion forklift options is set to step up a gear with… Read more »

OneCharge is spearheading the adoption of lithium forklift batteries in Latin America (LATAM). Max… Read more »

Battery technology for use within the cleaning industry has not significantly improved over the… Read more »

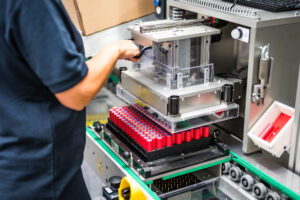

Automated internal logistic platforms, such as AGV and AMR, as well as other industrial… Read more »

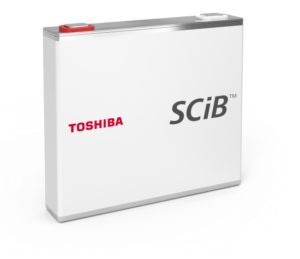

Toshiba Corporation has expanded its SCiB product offering with the launch of an innovative… Read more »

Aiming to continue business growth through a full upgrade and replacement of its warehouse… Read more »

MAT Foundry Group UK, a leading manufacturer of cast and machined products, has announced… Read more »

Nearly a quarter of all Toyota electric-powered forklift trucks ordered for delivery in the… Read more »

Lithion Recycling and UgoWork have signed a collaboration agreement for the recycling of lithium-ion… Read more »

Phil Ireland, Programme Leader 20/20 Platform at Hyster Europe, discusses the latest advances in… Read more »

Three new “lithium-ion ready” Platform Pallet Truck models, ideal for maximising productivity in intense… Read more »

An ultra-compact lithium-ion pallet truck for loads up to 1.5 tonnes has been launched… Read more »

Hiremech has completed the delivery of 15 new Hyster machines, fitted with Lithium Ion… Read more »

AMAB has recently chosen Toyota Material Handling as a partner for their lithium-ion trucks.… Read more »

Third party multi-temperature warehousing and logistics network, Norish, operates lithium-ion battery-powered Flexi articulated VNA… Read more »

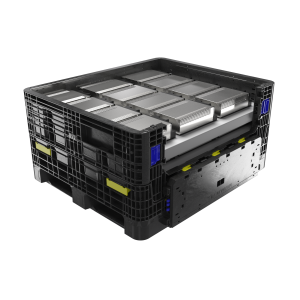

Amidst the rise of e-mobility in the automotive industry, Orbis Europe has developed a… Read more »

CWT Commodities has transformed its operations after purchasing five new Mitsubishi EDiA forklift trucks… Read more »

Hyster has launched its new J7.0–9.0XNL forklift series with fully integrated lithium-ion batteries. The… Read more »

Clark Europe is boosting its presence still further in the warehouse sector with a… Read more »

Flux Power Holdings, a developer of advanced lithium-ion batteries for commercial and industrial equipment… Read more »

The growing demand for alternative power solutions continues to drive evolution. This sparks opportunities… Read more »

Alternative power solutions are a rapidly growing aspect of the materials handling industry as… Read more »

Battery manufacturer Exide Technologies (www.exide.com), a global provider of stored electrical energy solutions, has… Read more »

Stöcklin Logistik AG has developed what it claims is the world’s first lithium-ion battery… Read more »

Third party multi-temperature warehousing and logistics network, Norish, has introduced lithium-ion battery-powered Flexi articulated… Read more »

Linde Material Handling is expanding its lithium-ion battery portfolio. For trucks in the load… Read more »

Alternative power solutions are a rapidly growing aspect of the materials handling industry as… Read more »

From the high point of the 1960’s when nearly 70 per cent of all… Read more »

Hyster Europe presented 360-degree solutions for warehouse and logistics applications at LogiMAT 2019, including… Read more »

Motive power specialist EnerSys is set to introduce advanced lithium ion technology to its… Read more »

Jungheinrich AG and battery specialist Triathlon Holding GmbH have come together to found JT… Read more »

Linde Material Handling will deliver several hundred industrial trucks to BLG Logistics, an international… Read more »

Logistics provider Dachser says it plans to replace all of its roughly 6,000 ground… Read more »

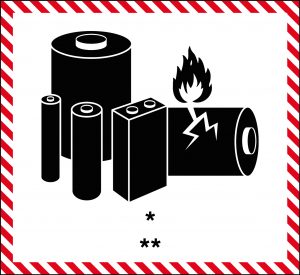

Sign and identification specialist Brady Corporation is offering new, compliant Lithium battery truck signs… Read more »

Jungheinrich UK has provided leading independent paper merchant, Premier Paper, with the UK’s first… Read more »

The last gap has been filled, according to Linde. That’s because the largest Linde… Read more »

As carmakers continue to launch electric vehicles, the need to protect batteries is a… Read more »

Linde Material Handling is to offer a flexible battery rental concept which the company… Read more »

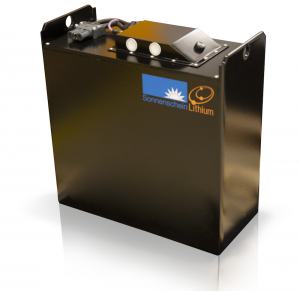

Chosen for their low weight and high efficiency, lithium-ion batteries are a central part… Read more »

Many an industrial truck operator considers switching from lead-acid batteries to lithium-ion technology when… Read more »

Forklift giant Linde says it plans to once again significantly expand its portfolio of… Read more »

Jungheinrich has received a major order for more than 1,000 lithium-ion vehicles and says… Read more »

Effective immediately, the Jungheinrich Group is providing a free 5-year warranty on all of… Read more »

Yale Europe Materials Handling aims to offer customers working in intensive applications improved efficiency… Read more »

Jungheinrich has continued to impress with its advances in energy saving technology at the… Read more »

All operators who use pallet trucks and double stackers in at least two-shift operation… Read more »

They made their debut at the companys World of Material Handling (WoMH) customer event… Read more »

Strict enforcement of existing regulations should be a priority rather than an outright ban… Read more »