For almost 40 years, more and more high-speed doors from Efaflex have been reliably… Read more »

For almost 40 years, more and more high-speed doors from Efaflex have been reliably… Read more »

It is among the most cutting-edge in the world: the new company site for… Read more »

A roller doors case study from the world of manufacturing offers useful pointers in… Read more »

Hörmann UK has launched two new transparent, high-speed spiral doors, the HS5040 TurboLux and… Read more »

Just 10 months after commencement on site, DSV is celebrating the practical completion of… Read more »

Facilitating fast and efficient movement of goods; minimising the risk of incidents; increasing workflow;… Read more »

A Bavarian body component manufacturer has installed doors which close at 1.8m per second,… Read more »

Union Industries, a leading British manufacturer of high-speed industrial doors, has completed the supply… Read more »

Industrial door manufacturer Dynaco has introduced two types of industrial doors: I-14 P panel… Read more »

With increased space including a first-time outdoor showing and a new IC truck, Linde… Read more »

Adler and Allan, which describes itself as the UK’s largest environmental and risk reduction… Read more »

Safe access pedestrian to the rear doors of trucks and container carrying vehicles in… Read more »

Paul Rudge of sara LBS examines the various loading-bay door choices, and highlights the… Read more »

Every industry, from retail to construction, relies on its supply chain for processes and… Read more »

Hörmann Transdek have announced that for the first time ever they are opening their… Read more »

Online to inflight, ecommerce is transforming international express courier services, writes Matthew Ware, CEO… Read more »

Yusen Logistics (UK), a leading provider of logistics solutions, and SEGRO, owner, manager and… Read more »

Berry’s commitment to sustainability will take centre stage on its stand at this year’s… Read more »

Sustainable toilet paper brand Who Gives A Crap is partnering with all-electric courier Packfleet… Read more »

United Arrows, one of Japan’s leading fashion retail brands, has seen a significant increase… Read more »

Union Industries, one of the UK’s leading manufacturers of bespoke industrial doors, has helped… Read more »

ABM will present complete drive solutions for a wide range of intralogistics applications at… Read more »

EnerSys®, a global leader in stored energy solutions for industrial applications, will premier its… Read more »

The February ’24 issue of Logistics Business magazine: 84 pages of exclusive content spanning… Read more »

One of Britain’s leading bakery brands, Warburtons, has selected Tiger Trailers to supply 38… Read more »

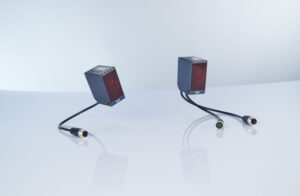

With the launch of its next-generation DT80 distance sensor, SICK claims to have revised… Read more »

Wabtec has announced its entrance into the rail telematics market via an agreement with… Read more »

Intralogistics specialist Linde Material Handling and the Aschaffenburg University of Applied Sciences (UAS) presented… Read more »

Customized solutions designed primarily for either indoor or outdoor use can now be implemented… Read more »

At the height of the COVID-19 pandemic, organisations were forced to take bold steps… Read more »

St. Modwen Logistics, one of the UK’s leading logistics developers and managers, has successfully… Read more »

Noone Transport, based in Co. Meath, Ireland, is undergoing a period of significant investment… Read more »

Hyster has introduced a new Reach Truck that works inside and outside providing even… Read more »

In a time of increasing demands on delivery speed and quality, it is crucial… Read more »

As demand for high-quality sustainable warehouse space strengthens, Logicor, one of Europe’s leading owner,… Read more »

Christmas is two months away. This means that the peak season is now starting… Read more »

Oceaneering International, Inc. announces that its Oceaneering Mobile Robotics (OMR) business successfully completed a… Read more »

Extended value creation cycles, used equipment in premium quality, sustainability and circular concepts –… Read more »

A division of Ambrosi S.r.l., ONO Lean Logistics has partnered with the METALSISTEM Group.… Read more »

After enduring five years of isolation in an abandoned Armenian zoo, Ruben, known as… Read more »

Yale Lift Truck Technologies has launched a new Outdoor Reach Truck, which it says… Read more »

Whether you agree that there is a climate change crisis or otherwise, it’s indisputable… Read more »

The September ’23 issue of Logistics Business magazine: 76 pages of exclusive content spanning… Read more »

In a world where rising bills seem to be the norm for families and… Read more »

Yale Lift Truck Technologies has launched two specially engineered operator assistance options to support… Read more »