Timber Strapping Machines on Show at Ligna

25th April 2019

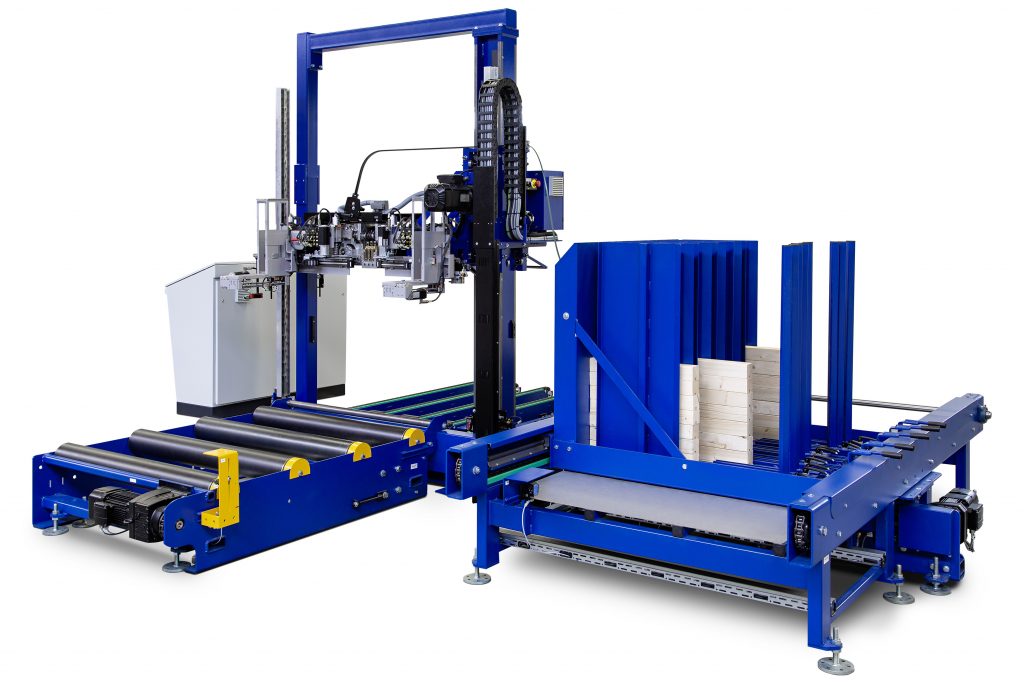

Mosca is presenting a new variant of its timber-specialist KOV-111-16, including a high-performance sealing unit, at Ligna 2019. The strapping unit has a tensile force of up to 7,000 newtons and allows the use of 19-mm strapping material for securing heavy products. The machine is also equipped with a scantling device and a fully automated edge protection setter. This makes it an ideal choice for businesses that need to quickly and efficiently secure large volumes of timber products for transport with minimal downtime. The Mosca display in Hall 16 (B12) in Hannover at the end of next month will also feature the MK-50, a particularly solid machine for strapping non-palleted products. The RO-M-RI and the RO-MP-6 T, which are especially suited to bundling long, narrow products such as roof battens or profiled timber, round out the Mosca portfolio for the timber industry.

When large quantities of sawn wood, chipboard, or other timber products are prepared for transport, the strapping technology must work smoothly and efficiently. Downtimes, especially for refilling consumables such as strapping, scantlings, and edge protection for securing the product must be as short as possible. This is the only way the process of securing goods for transport can keep pace with upstream production systems. “We have created a new variant of the KOV-111-16 with a scantling device and edge protection setter to master this challenge with a large magazine,” says Mosca GmbH CEO Timo Mosca. “Combined with the high-performance sealing unit we have developed, this gives us a solution that is specially tailored to the wood industry.” Integrated into conveying systems made by Mosca or other manufacturers, the fully automated machine feeds scantlings under the product to be strapped and protects the upper edges with solid cardboard.