Latest Digital Fleet Management Modules Revealed by Linde

21st September 2018

Linde Material Handling has revealed new modules for its ‘connect’ fleet management system at the Intralogistics Safety Forum, held in Aschaffenburg on September 20. The digital applications ‘Zone Intelligence’ and ‘Truck Mapping’ aim to utilize various technologies to make the use of industrial trucks even safer and more transparent.

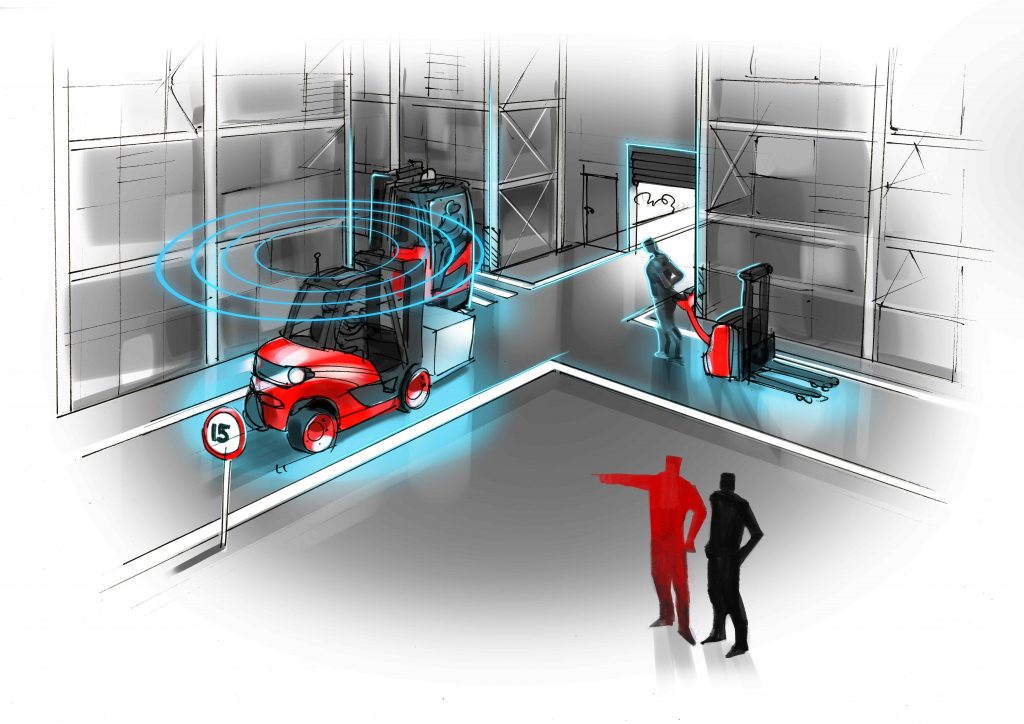

Zone Intelligence will be available both as a retrofit solution and ex works from the beginning of next year, and is claimed as another significant step towards greater safety in halls and other indoor environments. Currently, drivers themselves can determine speed and to what extent they reduce this speed at crossings or in narrow aisles. The same applies to driving with the lift mast raised too far. Collisions with roller shutters or ceiling supports caused by carelessness result in damage amounting to millions of euros every year. Linde’s new sensor-based assistance system aims to mitigate these potentially hazardous and costly situations. It allows fleet operators to define specific zones in warehouses and production areas in which the truck speed is automatically reduced.

It works using broadband radio signals in the 4-gigahertz range. These signals are exchanged between stationary sensors and a sensor on the vehicle, and they even pass through walls and pillars. To define the various zones, the fleet manager uses hall or plant layout maps which are uploaded to the computer via the connect:desk software. In the application, the various zones are configured one by one using a graphic tool, and specific parameters are assigned to them. These include the range around a defined anchor point, the so-called Zone Marker, as well as, for example, the size of the braking area. The new assistance system focuses on four fields of application: firstly, selective speed adjustment, which always takes effect when the truck approaches critical locations – for example, blind corners, crossings or intersections – that pose a general hazard potential. Secondly, it is possible to adjust the speed for areas with, for example, frequent pedestrian traffic. The third field is roller shutters or passageways, and the fourth is speed control on uneven ground.

Zone Intelligence is the second assistance system from Linde that uses ultra-wideband technology (UWB) to further reduce the risk of accidents. The Linde Safety Guard has been available since the start of this year to warn forklift drivers and pedestrians about each other via fixed installations on the truck and mobile units carried on the body. These devices not only give an acoustic and visual alarm, but also vibrate so that pedestrians can actually ‘feel’ there might be danger ahead. The advantage provided by UWB technology is used here, too: The radio waves can ‘see through’ walls, shelves and gates so that, for example, a pedestrian is warned of an approaching truck before a door opens. Another advantage is that there is no interference with other networks such as WLAN, Bluetooth or RFID.

Truck Mapping provides a bird’s eye view of the industrial truck’s operation. New telematics hardware locates each individual vehicle with an accuracy of up to 5m and visualizes it on a map. The larger the truck fleet and the more extensive the company premises are, the more useful this function is. A typical situation: A vehicle breaks down, but no one can tell the approaching service technician exactly where it is. An even more annoying case is when a truck has been stolen. Truck Mapping means fewer headaches for fleet managers. Now not only do they know where the vehicle is on the company’s premises when it is in need of repair, but they can also precisely locate it off-site which will help to deter thieves.